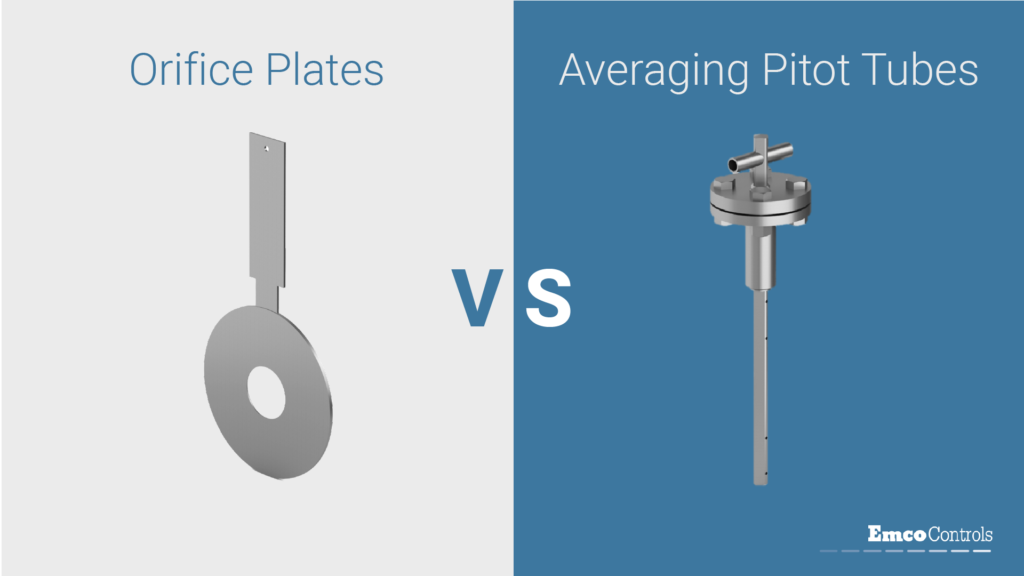

Differential pressure (DP) flow measurement is a crucial process in various industries, from oil and gas to carbon capture storage and water treatment etc.. Two common devices used for DP flow measurement are orifice plates and averaging Pitot tubes. Both have their advantages and are suited for different applications. In this article, we will explore the advantages of each and compare them to help you make an informed decision.

Orifice plates are known for their simplicity. They consist of a plate with a precisely drilled hole to create the differential pressure. This simplicity makes them reliable and easy to maintain and replace. They have no moving parts, removing the risk of mechanical failure.

Orifice plates are cost-effective compared to many other flow measurement devices. The initial investment is relatively low, making them a favorable option for projects with budget constraints.

Orifice plates can be used in a wide range of applications, from clean liquids to gases with solids. They are versatile and suitable for both low and high-pressure systems.

Orifice plate design and installation follow well-documented industry standards, ensuring accuracy and repeatability in measurements.

They provide a precise measurement of flow velocity by averaging the pressures at multiple points within a pipe, reducing the impact of turbulence.

Averaging Pitot tubes have lower permanent pressure loss compared to orifice plates. This means they are not as affected by the pressure and flow rate, making them efficient for long-term operation.

Averaging Pitot tubes can be installed in existing pipe works without adding flanges. This significantly lowers the total cost a flow meter installation.

These devices have no moving parts, reducing the need for frequent maintenance. Their robust design allows them to withstand harsh conditions. A purge unit can be added if the process consists of solids that can cause blockage.

If the focus is high accuracy, then the orifice plate should be the preferred choice. The averaging Pitot tube requires a quite long straight pipe run to be able to deliver the same high accuracy. However, the repeatability of the Pitot tube is quite high, so the accuracy is reliable and constant.

Orifice plates as a standalone product are generally more cost-effective than averaging Pitot tubes, however looking at the full installation the orifice plate requires orifice flanges meaning the total cost of a flow measurement can surpass the cost of the Pitot Tube

Averaging Pitot tubes have a much lower permanent pressure loss.

Both Orifice plates and Pitot tubes are versatile and suitable for a wide range of applications. When pipe sizes become larger than 500-750 mm, Pitot tubes scalability takes the advantage.

Both devices are low-maintenance due to their lack of moving parts. The installation of the Pitot tube makes it extremely easy to replace.

In summary, orifice plates and averaging Pitot tubes are both valuable tools for differential pressure flow measurement, each with its own set of advantages. Orifice plates are cost-effective, reliable, and versatile, making them a solid choice for many applications. On the other hand, averaging Pitot tubes offer lower installation cost, lower pressure loss, and is better great for larger pipe sizes

The choice between these two devices ultimately depends on your specific application, budget, and accuracy requirements. Consider the nature of your fluid, the level of accuracy needed, and the long-term operating costs to make an informed decision. Regardless of your choice, proper installation and maintenance are essential to ensure accurate and reliable flow measurements.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-advertisement | 1 year | Set by the GDPR Cookie Consent plugin, this cookie is used to record the user consent for the cookies in the "Advertisement" category . |

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| elementor | never | This cookie is used by the website's WordPress theme. It allows the website owner to implement or change the website's content in real-time. |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |

| Cookie | Duration | Description |

|---|---|---|

| _ga | 2 years | The _ga cookie, installed by Google Analytics, calculates visitor, session and campaign data and also keeps track of site usage for the site's analytics report. The cookie stores information anonymously and assigns a randomly generated number to recognize unique visitors. |

| _ga_* | 1 year 1 month 4 days | Google Analytics sets this cookie to store and count page views. |

| _gat_UA-* | 1 minute | Google Analytics sets this cookie for user behaviour tracking. |

| _gat_UA-151202324-1 | 1 minute | A variation of the _gat cookie set by Google Analytics and Google Tag Manager to allow website owners to track visitor behaviour and measure site performance. The pattern element in the name contains the unique identity number of the account or website it relates to. |

| _gid | 1 day | Installed by Google Analytics, _gid cookie stores information on how visitors use a website, while also creating an analytics report of the website's performance. Some of the data that are collected include the number of visitors, their source, and the pages they visit anonymously. |

| CONSENT | 2 years | YouTube sets this cookie via embedded YouTube videos and registers anonymous statistical data. |

| VISITOR_INFO1_LIVE | 5 months 27 days | YouTube sets this cookie to measure bandwidth, determining whether the user gets the new or old player interface. |

| YSC | session | Youtube sets this cookie to track the views of embedded videos on Youtube pages. |

| yt-remote-connected-devices | never | YouTube sets this cookie to store the user's video preferences using embedded YouTube videos. |

| yt-remote-device-id | never | YouTube sets this cookie to store the user's video preferences using embedded YouTube videos. |

| yt.innertube::nextId | never | YouTube sets this cookie to register a unique ID to store data on what videos from YouTube the user has seen. |

| yt.innertube::requests | never | YouTube sets this cookie to register a unique ID to store data on what videos from YouTube the user has seen. |