Description

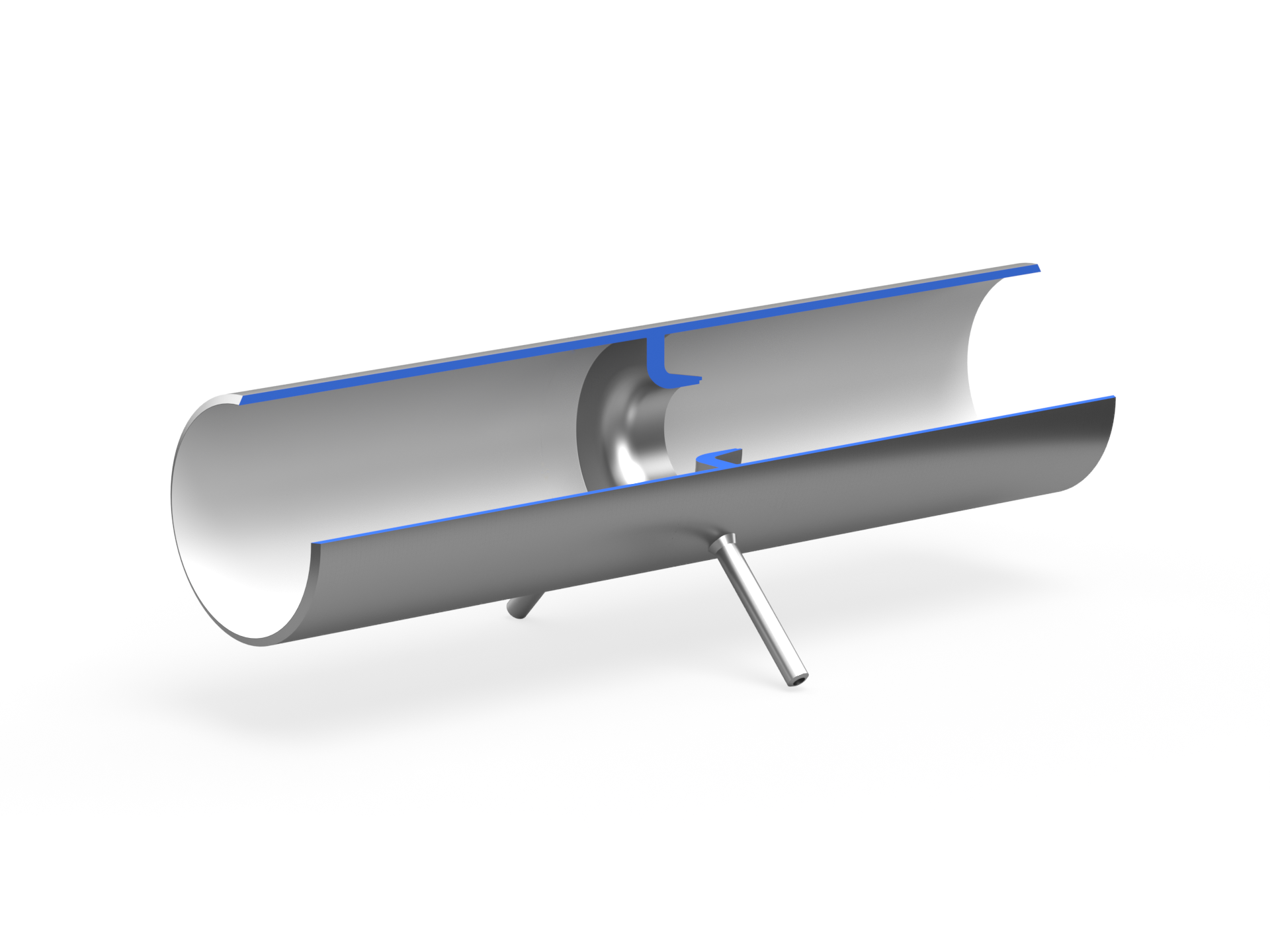

EMCO ISA Nozzles are used as primary elements in flow measurement of steam, liquid and gas according to the differential pressure principal and in accordance with ISO 5167-3. In the ISO 5167-3 standard the geometry and method of use are specified for nozzles to determine the flow-rate of the flowing liquid in the conduit when the nozzles are inserted in a conduit. The ISA 1932 nozzle is made from a solid bar welded into a pipe section. The fact that it is constructed in this way makes it less material intensive compared to a Venturi Nozzle which is made from solid bar. Providing high accuracy and inducing little permanent pressure loss, the ISA 1932 nozzle har has certain advantages which makes it particulerly well suited for the following:

|

|

|

|

Design and calculation standards

|

ISO 5167-3

|

|

Sizes

|

DN 50 - DN 500

|

|

Pressure rating

|

PN 10 - 640, 150 - 2500 lbs

|

|

β (d/D)

|

Preferred range 0,3 < β < 0,8

|

|

Material

|

Carbon steel P250GH, AISI 316, 16Mo3, 13CrMo4-5, 10CrMo9-10, WB 36, X20CrMoV121, P91, P92, other materials on request

|

|

Mounting style

|

Weld ends according to DIN 2559 or ANSI B16.25

|

|

Pressure taps

|

Ø 21.3 mm, 24 mm, 26.9mm, 3/8", 1/2" BSP, 1/2" NPT

|

|

Tappings

|

Single pressure tappings or annular ring (Type DRS)

|

|

|

|

|

Accuracy

|

0,8 % for β 0,6 (according to ISO 5167-3)

|

|

Pressure loss

|

Depending on β, for β equal to 0,6 : ca. 60 % of the differential pressure measured

|

|

Limits for Reynolds No

|

2*10^4 < ReD < 1*10^7 according to ISO 5167-3

|

|

|

|

|

Shut-off valves

|

|

|

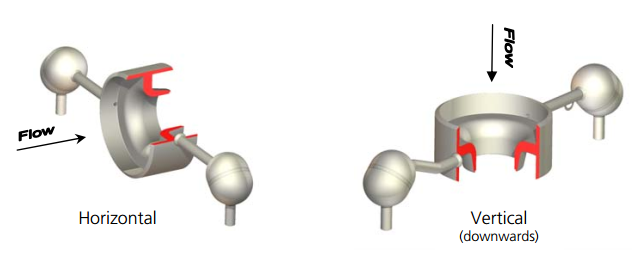

Condensing chamber unit for steam flow

|

EMCO ISA 1932 nozzle with condensing chambers

for steam flow measurement in a horizontal or vertical pipe line

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-advertisement | 1 year | Set by the GDPR Cookie Consent plugin, this cookie is used to record the user consent for the cookies in the "Advertisement" category . |

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| elementor | never | This cookie is used by the website's WordPress theme. It allows the website owner to implement or change the website's content in real-time. |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |

| Cookie | Duration | Description |

|---|---|---|

| _ga | 2 years | The _ga cookie, installed by Google Analytics, calculates visitor, session and campaign data and also keeps track of site usage for the site's analytics report. The cookie stores information anonymously and assigns a randomly generated number to recognize unique visitors. |

| _ga_* | 1 year 1 month 4 days | Google Analytics sets this cookie to store and count page views. |

| _gat_UA-* | 1 minute | Google Analytics sets this cookie for user behaviour tracking. |

| _gat_UA-151202324-1 | 1 minute | A variation of the _gat cookie set by Google Analytics and Google Tag Manager to allow website owners to track visitor behaviour and measure site performance. The pattern element in the name contains the unique identity number of the account or website it relates to. |

| _gid | 1 day | Installed by Google Analytics, _gid cookie stores information on how visitors use a website, while also creating an analytics report of the website's performance. Some of the data that are collected include the number of visitors, their source, and the pages they visit anonymously. |

| CONSENT | 2 years | YouTube sets this cookie via embedded YouTube videos and registers anonymous statistical data. |

| VISITOR_INFO1_LIVE | 5 months 27 days | YouTube sets this cookie to measure bandwidth, determining whether the user gets the new or old player interface. |

| YSC | session | Youtube sets this cookie to track the views of embedded videos on Youtube pages. |

| yt-remote-connected-devices | never | YouTube sets this cookie to store the user's video preferences using embedded YouTube videos. |

| yt-remote-device-id | never | YouTube sets this cookie to store the user's video preferences using embedded YouTube videos. |

| yt.innertube::nextId | never | YouTube sets this cookie to register a unique ID to store data on what videos from YouTube the user has seen. |

| yt.innertube::requests | never | YouTube sets this cookie to register a unique ID to store data on what videos from YouTube the user has seen. |