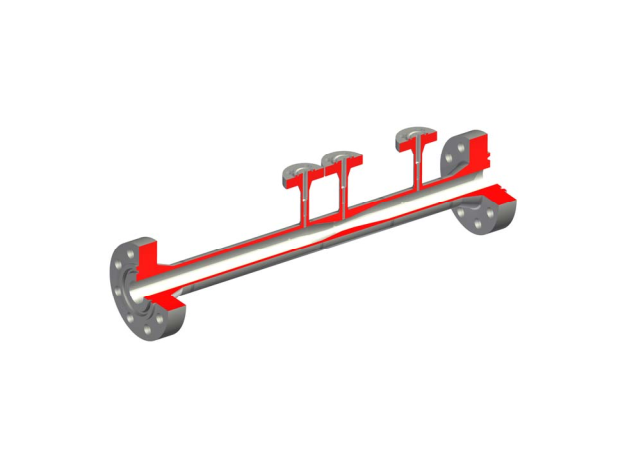

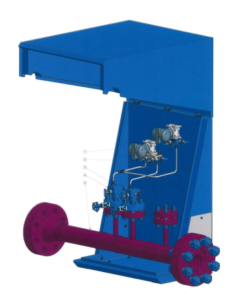

The EMCO wet gas meter is used to measure the flow rate in natural gasses with a certain level of liquid present. Based on the classical venturi tube according to ISO 5167-4 with single pressure tappings. A third tapping may be applied for liquid flow rate determination using the pressure loss ratio method. The system consists of a classical venturi tube in a metering section. The wet gas meter is designed to perform reliable measurements in applications such as well testing, hydrocarbon metering and monitoring of critical factors such as water breakthrough.

|

|

|

|

Element type

|

Classical venturi tube, machined type

|

|

Design standards

|

ISO 5167-4, ISO/TR 15377, ASME MFC-3M, ASME MFC Report 19G-2008 Wet Gas Flow Metering Guideline ISO/TR 11583

|

|

Sizes

|

DN 50 - DN 250, 2” - 10"

|

|

Pressure rating

|

PN 10 - 640, 150 - 2500 lbs, ISO PN 20 - 420

|

|

β (d/D)

|

preferred range 0,4 < β < 0,75

|

|

Material

|

22Cr Duplex (standard), AISI 316, 25Cr Duplex

|

|

Mounting style

|

Flanges to ANSI B16.5 or hubs for clamp connection

|

|

Pressure taps

|

½”, ¾” or 1” flanges or hubs

|

|

Temperature tab

|

1½” flanged

|

|

Inlet cone

|

21 or 10,5°

|

|

Outlet cone

|

7-15°

|

|

|

|

|

Accuracy

|

1 % gas flow, 10% liquid flow

|

The system consists of a classical venturi tube in a metering section. Differential pressure transmitter(s), static pressure transmitter or multivariable transmitters, a thermowell and a temperature transmitter an instrument cabinet, a wet gas flow computer and an over reading correction algorithm and if required for liquid flow determination tracer dilution system.

The metering section shall be mounted in a horizontal pipe run with pressure tappings pointing up wards. Length of in- and outlet pipe are not critical. An inlet length of 5 times inner pipe diameter and an outlet length of 2 times is sufficient. Impulse lines from transmitters to meter tube shall be sloped.

Wet gas metering systems require period check of fluid composition to ensure reliable flow rate measurement. The span of time between each check depends on required accuracy and how quickly the composition of the flow rate change. EMCO Controls can provide the initial start-up of the system as well as periodic flow check on site.

Download the installation guide above for more detailed information.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-advertisement | 1 year | Set by the GDPR Cookie Consent plugin, this cookie is used to record the user consent for the cookies in the "Advertisement" category . |

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| elementor | never | This cookie is used by the website's WordPress theme. It allows the website owner to implement or change the website's content in real-time. |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |

| Cookie | Duration | Description |

|---|---|---|

| _ga | 2 years | The _ga cookie, installed by Google Analytics, calculates visitor, session and campaign data and also keeps track of site usage for the site's analytics report. The cookie stores information anonymously and assigns a randomly generated number to recognize unique visitors. |

| _ga_* | 1 year 1 month 4 days | Google Analytics sets this cookie to store and count page views. |

| _gat_UA-* | 1 minute | Google Analytics sets this cookie for user behaviour tracking. |

| _gat_UA-151202324-1 | 1 minute | A variation of the _gat cookie set by Google Analytics and Google Tag Manager to allow website owners to track visitor behaviour and measure site performance. The pattern element in the name contains the unique identity number of the account or website it relates to. |

| _gid | 1 day | Installed by Google Analytics, _gid cookie stores information on how visitors use a website, while also creating an analytics report of the website's performance. Some of the data that are collected include the number of visitors, their source, and the pages they visit anonymously. |

| CONSENT | 2 years | YouTube sets this cookie via embedded YouTube videos and registers anonymous statistical data. |

| VISITOR_INFO1_LIVE | 5 months 27 days | YouTube sets this cookie to measure bandwidth, determining whether the user gets the new or old player interface. |

| YSC | session | Youtube sets this cookie to track the views of embedded videos on Youtube pages. |

| yt-remote-connected-devices | never | YouTube sets this cookie to store the user's video preferences using embedded YouTube videos. |

| yt-remote-device-id | never | YouTube sets this cookie to store the user's video preferences using embedded YouTube videos. |

| yt.innertube::nextId | never | YouTube sets this cookie to register a unique ID to store data on what videos from YouTube the user has seen. |

| yt.innertube::requests | never | YouTube sets this cookie to register a unique ID to store data on what videos from YouTube the user has seen. |