Differential pressure (DP) flow measurement is a widely employed technique in industrial applications for accurately quantifying fluid flow rates. One crucial factor that significantly influences the accuracy of DP flow measurements is the Reynolds number. The Reynolds number is a dimensionless parameter that characterizes the flow regime and helps predict the transition between laminar and turbulent flow. In the realm of flow measurement, understanding the implications of Reynolds number is vital for obtaining reliable and precise results.

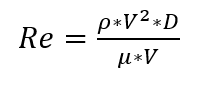

The Reynolds number (Re) is a dimensionless quantity used to predict the flow patterns in different fluid flow situations. It is defined as the ratio of inertial forces to viscous forces within a fluid. Mathematically, Re is expressed as:

Where:

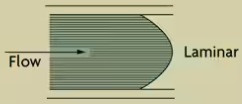

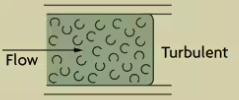

The Reynolds number is a critical parameter for predicting the flow regime. There are 3 types of flow regimes; Laminar, transitional and turbulent. Laminar flow occurs when the Reynolds number fall below 2000. Above 4000, the flow is considered turbulent. Values in between is called transitional flow.

In laminar flow, the fluid moves smoothly and predictably, with well-defined streamlines. The fluid velocity close to the wall is close to zero and at the center of the pipe there are not retaining forces. This means the fluid is flowing in different velocities across the flow profile. Laminar flow is seen at either low velocity or high viscosity fluids.

On the other hand, turbulent flow is characterized by chaotic, irregular fluid motion. This results in most of the fluid is moving at the same velocity.

The transition between laminar and turbulent flow is influenced by the Reynolds number.

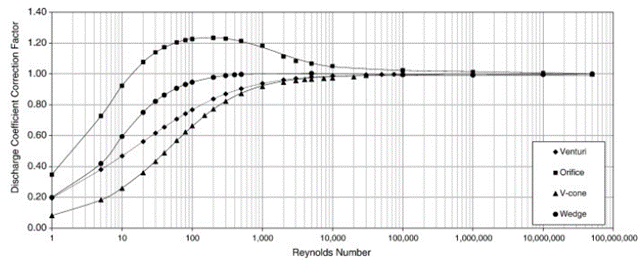

95% of DP flow measurement devices, such as orifice plates and venturis are designed for turbulent flow. The turbulent flow creates an even pressure distribution across the measurement device as opposed to laminar flows. This is evident when looking at discharge coefficient (Cd) over a wide range of Reynolds numbers. Cd is a dimensionless factor that relates the actual flow rate to the theoretically predicted flow rate. In laminar flows, Cd is variable. In turbulent flows, however, Cd is constant. Illustrated in the figure below. The higher the Reynolds number, the more reliable the flow measurement will be.

The Reynolds number can be helpful to understand how the flow acts, which is crucial for obtaining accurate and reliable results. Engineers must carefully consider the flow regime and choose appropriate measurement devices and calibration procedures to ensure the accuracy of flow rate measurements across varying Reynolds numbers. By appreciating the complexities introduced by different flow regimes, engineers can enhance the precision and reliability of DP flow measurements in diverse industrial applications.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-advertisement | 1 year | Set by the GDPR Cookie Consent plugin, this cookie is used to record the user consent for the cookies in the "Advertisement" category . |

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| elementor | never | This cookie is used by the website's WordPress theme. It allows the website owner to implement or change the website's content in real-time. |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |

| Cookie | Duration | Description |

|---|---|---|

| _ga | 2 years | The _ga cookie, installed by Google Analytics, calculates visitor, session and campaign data and also keeps track of site usage for the site's analytics report. The cookie stores information anonymously and assigns a randomly generated number to recognize unique visitors. |

| _ga_* | 1 year 1 month 4 days | Google Analytics sets this cookie to store and count page views. |

| _gat_UA-* | 1 minute | Google Analytics sets this cookie for user behaviour tracking. |

| _gat_UA-151202324-1 | 1 minute | A variation of the _gat cookie set by Google Analytics and Google Tag Manager to allow website owners to track visitor behaviour and measure site performance. The pattern element in the name contains the unique identity number of the account or website it relates to. |

| _gid | 1 day | Installed by Google Analytics, _gid cookie stores information on how visitors use a website, while also creating an analytics report of the website's performance. Some of the data that are collected include the number of visitors, their source, and the pages they visit anonymously. |

| CONSENT | 2 years | YouTube sets this cookie via embedded YouTube videos and registers anonymous statistical data. |

| VISITOR_INFO1_LIVE | 5 months 27 days | YouTube sets this cookie to measure bandwidth, determining whether the user gets the new or old player interface. |

| YSC | session | Youtube sets this cookie to track the views of embedded videos on Youtube pages. |

| yt-remote-connected-devices | never | YouTube sets this cookie to store the user's video preferences using embedded YouTube videos. |

| yt-remote-device-id | never | YouTube sets this cookie to store the user's video preferences using embedded YouTube videos. |

| yt.innertube::nextId | never | YouTube sets this cookie to register a unique ID to store data on what videos from YouTube the user has seen. |

| yt.innertube::requests | never | YouTube sets this cookie to register a unique ID to store data on what videos from YouTube the user has seen. |