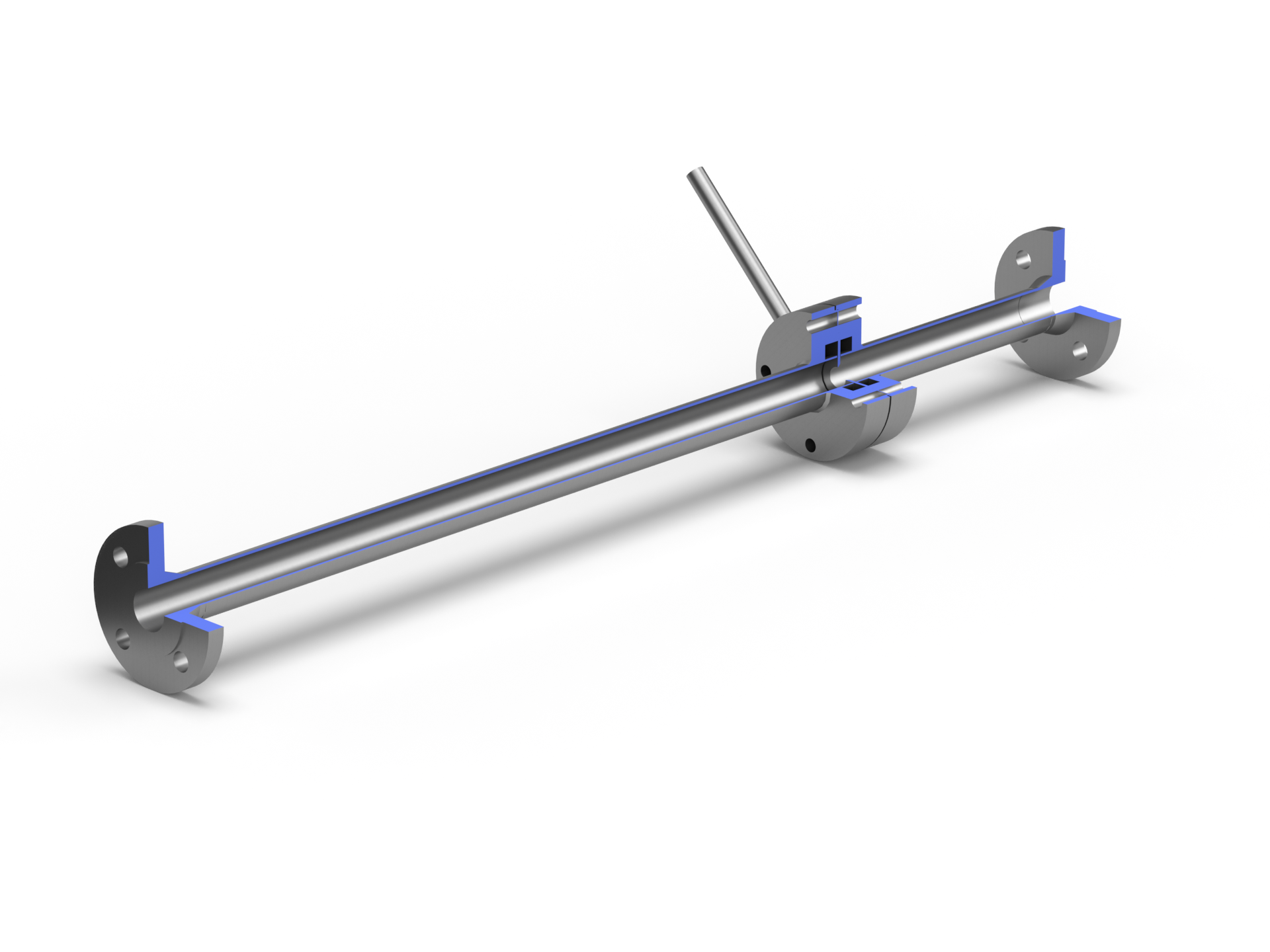

The EMCO Meter Run is used as a primary element in flow measurement of liquid, gas and steam applications based on the differential pressure principle. According to this working principle, the orifice plate creates a flow restriction within the meter run to allow measurement of the resulting pressure drop and flow rate. Our orifice plates have been tested and tried for over 50 years and measure up to the highest industry and compliance standards.

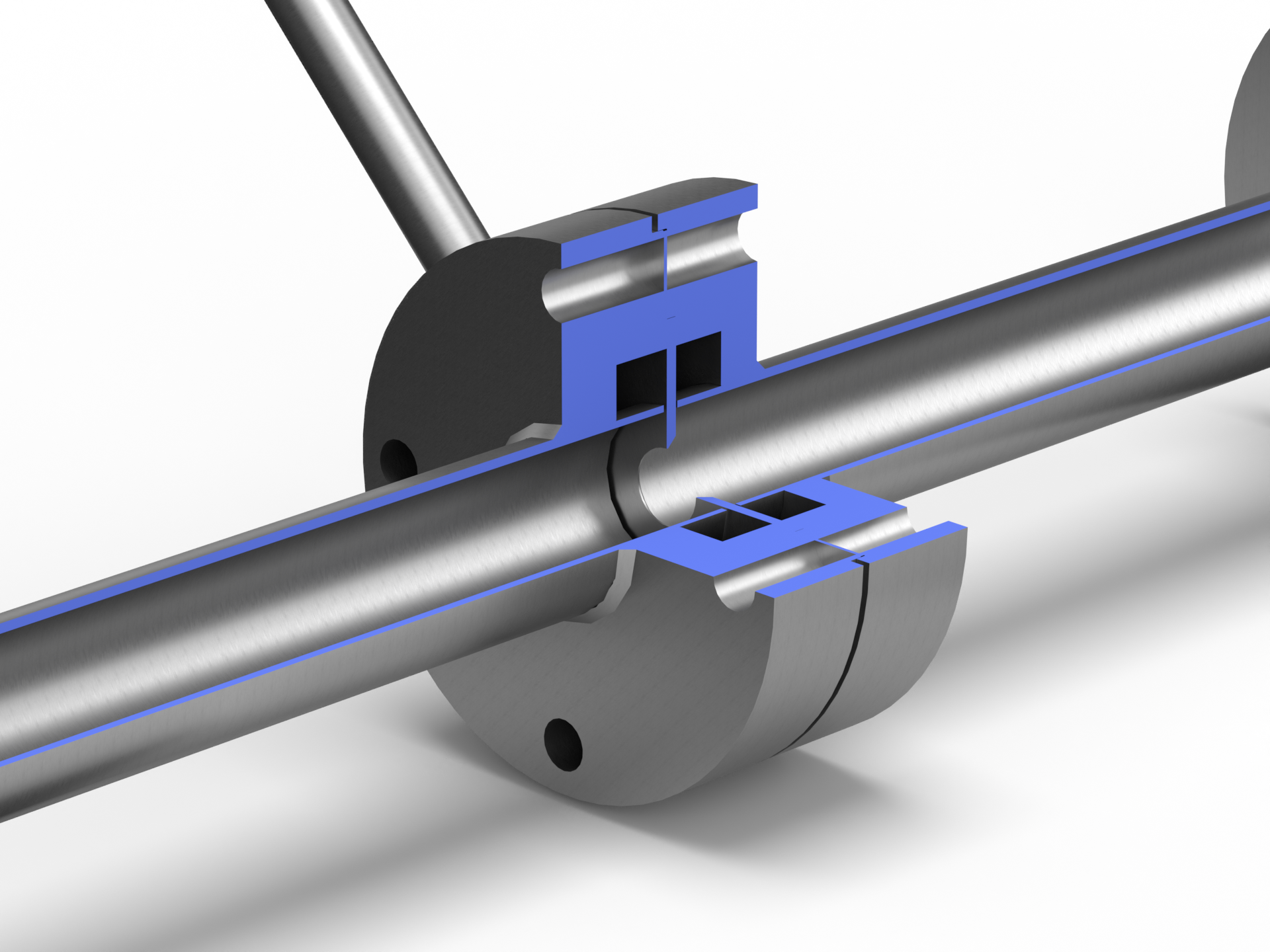

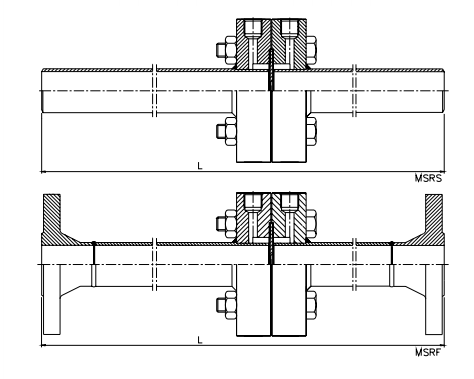

The Meter Run Series MSRS and MSRF combine the orifice plate with a straight pipe run ro enhance the flow profile. The construction includes carrier rings and corner pressure tappings.

|

|

|

|

Design and calculation standards

|

ISO 5167, ISO/TR 15377, BS 1042, ASME Fluid Meters, DIN 19205Shell Flow Meter Engineering Handbook

|

|

Sizes

|

DN 10 – DN 50, 3/8” - 2"

|

|

Pressure rating

|

PN 10 - 400, 150 - 2500 lbs

|

|

Plate thickness

|

3 mm

|

|

Vent or drain hole

|

On request

|

|

Plate material

|

AISI 316, other on request.

|

|

Carrier ring and pipe material

|

Carbon steel, AISI 316, other materials on request

|

|

Pipe run

|

Can be honed for increased accuracy

|

|

Flange standards

|

DIN, AISI B 16.5

|

|

Pressure taps

|

3/8", 1/2" BSP, Ø 12 mm, 1/2" NPT.int.

|

|

Male tappings

|

On request

|

|

Connection

|

Weld ends or flanges with flat or raised face or groove according to DIN 2526, 2513 or 2512, or RF and RTJ according to ANSI B 16.5

|

|

Orifice plate shapes

|

Square edge concentric, other shapes on request. Orifice plates are bevelled on the downstream side

|

|

Marking

|

The orifice plate is marked with "+" and"-" and flow direction.

|

|

|

|

|

Accuracy

|

+/- 0,8 - 1 %

|

|

Pressure loss

|

Depending on β, for β equal to 0,6 : ca. 60 % of the differential pressure measured

|

|

Limits for Reynolds No

|

Re > 1260 x β2 D according to ISO 5167 2000 < Re < 108 according to ASME MFC-3M

|

|

|

|

|

Shut-off valves and condensing chambers for steam flow measurement. Flange assembly complete with bolts, nuts and gaskets

|

DN |

Inches |

Total length (mm) |

|---|---|---|

|

10

|

3/8”

|

400

|

|

15

|

½”

|

550

|

|

20

|

¾”

|

700

|

|

25

|

1”

|

900

|

|

32

|

1 ¼”

|

1100

|

|

40

|

1 ½”

|

1300

|

|

50

|

2”

|

1500

|

Before installation, the orifice plate must be kept clean and protected against corrosion and physical damage. It is also important that you pay careful attention to to the sharp edge of the plate. Once ensured that it is clean, install the orifice plate carefully such that the orifice bore aligns with the centre of the pipeline. Tap location varies depending on whether it is used for liquid, gas or steam. It is not supplied with any safety devices and must not be used for higher pressure, than stated on the name plate. The pipe system must therefore be equipped with a safety device. However, this type of primary element requires no special maintenance.

Download the installation guide above for more detailed information.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-advertisement | 1 year | Set by the GDPR Cookie Consent plugin, this cookie is used to record the user consent for the cookies in the "Advertisement" category . |

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| elementor | never | This cookie is used by the website's WordPress theme. It allows the website owner to implement or change the website's content in real-time. |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |

| Cookie | Duration | Description |

|---|---|---|

| _ga | 2 years | The _ga cookie, installed by Google Analytics, calculates visitor, session and campaign data and also keeps track of site usage for the site's analytics report. The cookie stores information anonymously and assigns a randomly generated number to recognize unique visitors. |

| _ga_* | 1 year 1 month 4 days | Google Analytics sets this cookie to store and count page views. |

| _gat_UA-* | 1 minute | Google Analytics sets this cookie for user behaviour tracking. |

| _gat_UA-151202324-1 | 1 minute | A variation of the _gat cookie set by Google Analytics and Google Tag Manager to allow website owners to track visitor behaviour and measure site performance. The pattern element in the name contains the unique identity number of the account or website it relates to. |

| _gid | 1 day | Installed by Google Analytics, _gid cookie stores information on how visitors use a website, while also creating an analytics report of the website's performance. Some of the data that are collected include the number of visitors, their source, and the pages they visit anonymously. |

| CONSENT | 2 years | YouTube sets this cookie via embedded YouTube videos and registers anonymous statistical data. |

| VISITOR_INFO1_LIVE | 5 months 27 days | YouTube sets this cookie to measure bandwidth, determining whether the user gets the new or old player interface. |

| YSC | session | Youtube sets this cookie to track the views of embedded videos on Youtube pages. |

| yt-remote-connected-devices | never | YouTube sets this cookie to store the user's video preferences using embedded YouTube videos. |

| yt-remote-device-id | never | YouTube sets this cookie to store the user's video preferences using embedded YouTube videos. |

| yt.innertube::nextId | never | YouTube sets this cookie to register a unique ID to store data on what videos from YouTube the user has seen. |

| yt.innertube::requests | never | YouTube sets this cookie to register a unique ID to store data on what videos from YouTube the user has seen. |