EMCO Controls manufactured its first venturi tube in 1987, which was also the first delivery to an international customer. The Venturi tube therefore paved the way for our international endeavours and has been a core product ever since. In this article, we will offer you a surface-level understanding of this important piece of flow instrumentation.

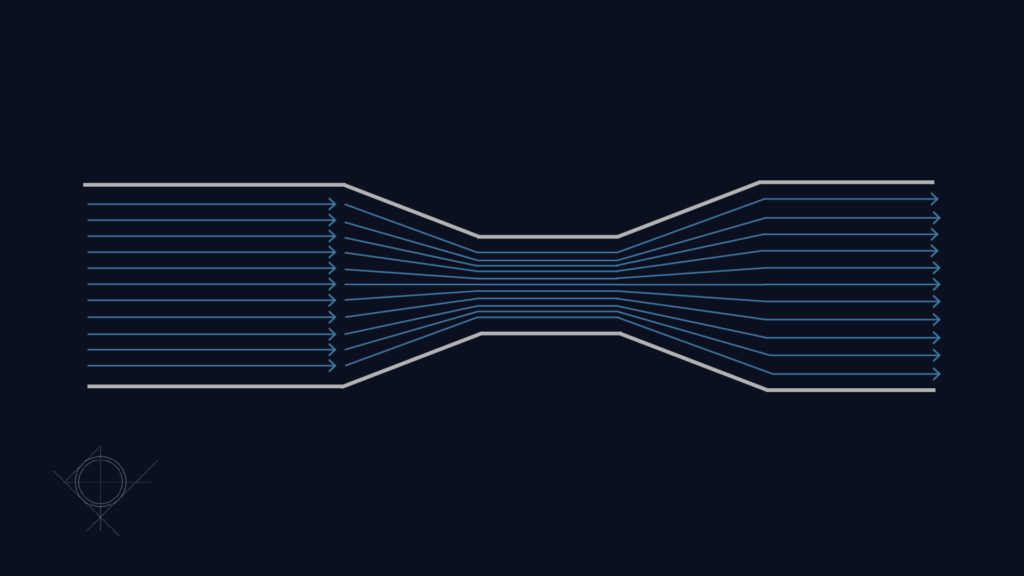

A venturi tube is a short pipe with an inner constriction that can be used to measure fluid. The Venturi tube is designed by and named after the 18th–19th-century Italian physicist Giovanni Battista Venturi, who noted the effects that constricted channels have on fluid flow. Based on his observations, he designed a device with a narrow throat in the middle, causing a phenomenon known as the Venturi effect.

The Venturi effect states that the pressure will drop when a fluid passes through the tube and enters the narrow throat, which is the opposite of what one would immediately think. This relationship between pressure and velocity can be used to mix certain substances such as gasses or fluid with air at a continuous rate.

The natural design of the Venturi makes it suitable for applications requiring a low permanent pressure drop.

The Venturi effect is widely used in industry and everyday products to mix different substances at controlled rates. Here are some examples of where it is used:

There are two different types of Venturi tubes which each have their own specific advantages. The 2 types differ in such a way that the body of the Venturi tube can either be welded from rolled sheet or machined from solid bar. This results in a difference in accuracy, with the machined process ensuring a more precise internal diameter which gives it an accuracy of 1% as opposed to 1,5% for welded sheet Venturies.

The machined Venturi tube allows us to make a Venturi body with large wall thickness and is well-suited for:

The welded sheet Venturi is welded together in sections thus making it suitable for larger Venturi diameters in low pressure applications. Welded sheet Venturi tubes are ideal for:

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-advertisement | 1 year | Set by the GDPR Cookie Consent plugin, this cookie is used to record the user consent for the cookies in the "Advertisement" category . |

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| elementor | never | This cookie is used by the website's WordPress theme. It allows the website owner to implement or change the website's content in real-time. |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |

| Cookie | Duration | Description |

|---|---|---|

| _ga | 2 years | The _ga cookie, installed by Google Analytics, calculates visitor, session and campaign data and also keeps track of site usage for the site's analytics report. The cookie stores information anonymously and assigns a randomly generated number to recognize unique visitors. |

| _ga_* | 1 year 1 month 4 days | Google Analytics sets this cookie to store and count page views. |

| _gat_UA-* | 1 minute | Google Analytics sets this cookie for user behaviour tracking. |

| _gat_UA-151202324-1 | 1 minute | A variation of the _gat cookie set by Google Analytics and Google Tag Manager to allow website owners to track visitor behaviour and measure site performance. The pattern element in the name contains the unique identity number of the account or website it relates to. |

| _gid | 1 day | Installed by Google Analytics, _gid cookie stores information on how visitors use a website, while also creating an analytics report of the website's performance. Some of the data that are collected include the number of visitors, their source, and the pages they visit anonymously. |

| CONSENT | 2 years | YouTube sets this cookie via embedded YouTube videos and registers anonymous statistical data. |

| VISITOR_INFO1_LIVE | 5 months 27 days | YouTube sets this cookie to measure bandwidth, determining whether the user gets the new or old player interface. |

| YSC | session | Youtube sets this cookie to track the views of embedded videos on Youtube pages. |

| yt-remote-connected-devices | never | YouTube sets this cookie to store the user's video preferences using embedded YouTube videos. |

| yt-remote-device-id | never | YouTube sets this cookie to store the user's video preferences using embedded YouTube videos. |

| yt.innertube::nextId | never | YouTube sets this cookie to register a unique ID to store data on what videos from YouTube the user has seen. |

| yt.innertube::requests | never | YouTube sets this cookie to register a unique ID to store data on what videos from YouTube the user has seen. |